RACER, Airbus Helicopters’ New Demonstrator, Takes First Flight with Avio Aero’s Innovative Technologies

The dream of producing a revolutionary new rotorcraft that can achieve maximum velocity with increased maneuverability, lower acoustics, and reduced emissions got a little closer to reality on April 25, when Airbus announced the first flight of RACER, a high-speed compound helicopter with a unique box-wing design that combines a traditional main rotor with two lateral rotors.

Three weeks later, during a special event, the RACER demonstrator model took flight at an Airbus test base in Marignane, France, just outside Marseille, in front of a crowd of roughly 150 industry officials, partners, and representatives of the European Union, which provided support for the helicopter’s development through the Clean Sky 2 research program, launched in 2017. Airbus, working with aviation industry partners such as Avio Aero, a GE Aerospace company headquartered in Turin, Italy, will continue testing RACER over the next two years in an effort to fine-tune its high-speed capabilities.

“With its 90 patents, RACER” — short for “Rapid and Cost-Effective Rotorcraft” — “is the perfect example of the level of innovation that can be achieved when European partners come together,” says Bruno Even, CEO of Airbus Helicopters. “This first flight is a proud moment for Airbus Helicopters and for our 40 partners in 13 countries. I look forward to watching this demonstrator pioneer high-speed capabilities and develop the eco-mode system that will contribute to reducing fuel consumption. RACER represents a turning point for the future of mobility, for civil, para-public, or defense needs.”

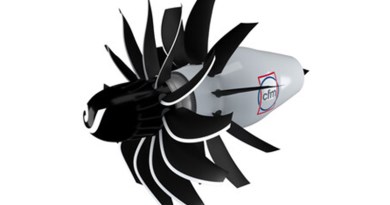

Airbus started designing RACER under the auspices of the Clean Sky 2 Program, the aim of which has been to “develop cleaner air transport technologies … capable of reducing CO2, NOx, and noise emissions by 20% to 30% compared to ‘state-of-the-art’ aircraft” that entered into service as of 2014. RACER is designed for short-to-medium-range flight in urban settings. The box-wing design provides aerodynamic efficiency; a metallic-composite airframe helps to lower overall weight; and a hybrid electric system allows one of its two engines to switch to standby while the helicopter is in cruise mode.

According to Airbus, this “dynamic configuration” is capable of reducing fuel consumption by 20%, which lowers CO2 emissions as well. What’s more, the shape and design of the rotors help to reduce noise levels by up to 20% while enabling RACER to fly at speeds 50% higher than conventional helicopters. In fact, the demonstrator is optimized for a cruise speed of 400 kilometers per hour (nearly 250 mph).

“For pilots, it will be an experiential leap from flying a traditional helicopter,” says Julien Guitton, RACER and European research program manager at Airbus Helicopters. “Just one button to switch to high speed with no transition between the hover and cruise phases.”

Avio Aero has been working with Airbus since 2015 on RACER’s transmission components. So far, Avio Aero has designed and built both the main gearbox (MGB) and the lateral gearboxes (LGB) for the demonstrator. To Marinella Marconi, RACER technical leader at Avio Aero, it’s what’s inside the gearboxes that makes all the difference. For instance, the LGBs are made from an innovative alloy that provides higher wear and temperature resistance (compared to typical metals and alloys used in gears in aeronautical power transmissions), and the LGB bearings are a hybrid combination of steel and ceramic material. “This material offers several benefits, including better performance in the event of poor lubrication, thanks to its low friction coefficient and greater lightness when compared to steel,” she says.

“RACER’s lateral gearboxes and the main gearbox have been constructed using cutting-edge materials and processes,” Marconi adds. “Last year, Avio Aero finalized an impressive amount of tasks: We delivered ground and flight MGB and LGB modules to Airbus Helicopters and we successfully completed the LGBs’ test campaign for the permit to fly. This project in partnership with Airbus Helicopters has been a great adventure, and Avio Aero took an active part in the construction of the very first example of this impressive aircraft.”

According to Guitton, the RACER demonstrator is the result of a shared vision. “I think that’s what energizes the project and reinforces the sense of community that distinguishes our team of partners,” he says. “It’s what allows us to overcome the challenges that such an innovation presents. No one is alone in facing them; we do it together. And this is what I appreciate about the RACER community, as well as Clean Aviation, which has the same spirit through the network of industry, research, and academia.”

Clean Aviation is the European Union’s public-private partnership leading the research and development of innovative new technologies to achieve more sustainable aviation practices. It picks up where the Clean Sky 2 program — which was sunsetted this year — leaves off, focusing on three key types of aircraft development: hybrid electric, ultra-efficient short to medium range, and disruptive technologies that will enable hydrogen power.

“The RACER is a demonstrator, and it’s just getting started,” Guitton says. “Now we’re going to open this exciting ‘flight domain’ phase to test all its capabilities, up to top speed,” and including load, range, and maneuverability. “We will do this thanks to more than 700 sensors installed around the entire test aircraft, and the flight envelope will take several months.”

Marconi attended the demonstration flight in Marignane along with some of her colleagues from Avio Aero. Christian Giordano, a manufacturing engineering manager who specializes in gearbox assembly, has been on the RACER team since 2019. “When the project was presented to me for the first time, I was shocked by the complexity,” he says, “but at the same time happy for the challenge.” Elena Alessio, who joined the RACER team in 2021 as a systems engineer, called it “a true honor” to witness RACER’s first flight. “Seeing the RACER flying was impressive and emotional,” she says.

Marconi attests to the effort that Avio Aero has poured into its work on the RACER program. “I’m privileged and proud to be here with my colleagues to see the RACER flying,” she says. “It’s the bright conclusion of a story that shows the resilience and determination of both the Avio Aero engineering and global supply chain teams. We’re helping to shape the future of flight within the helicopter and power transmission field.”