RTX’s Pratt & Whitney to demonstrate hydrogen-fueled turboprop technology under Canadian INSAT program

First phase of HyADES project will include tests on PW127XT engine fuel nozzle and combustor rig

Pratt & Whitney Canada will demonstrate hydrogen combustion technology on a PW127XT regional turboprop engine as part of a project supported by Canada’s Initiative for Sustainable Aviation Technology (INSAT). The project, named Hydrogen Advanced Design Engine Study (HyADES), will be in collaboration with Next Hydrogen Solutions Inc., which will develop high-efficiency, low-cost electrolyzers needed for establishing hydrogen production infrastructure. Pratt & Whitney is an RTX (NYSE: RTX) business.

“This collaborative project with INSAT enables us to develop key technologies for future hydrogen powered aircraft and complements our wider efforts to advance aviation sustainability through a range of pathways, including continued improvements to engine efficiency, hybrid-electric propulsion and compatibility with sustainable aviation fuel (SAF),” said Edward Hoskin, vice president, Engineering, Pratt & Whitney Canada. “While regional aviation represents one of the most promising use cases for hydrogen, the project will also demonstrate the versality of adapting the proven, highly efficient PW127XT turboprop engine to operate with low carbon alternative fuels and continues our legacy of technology leadership in this segment.”

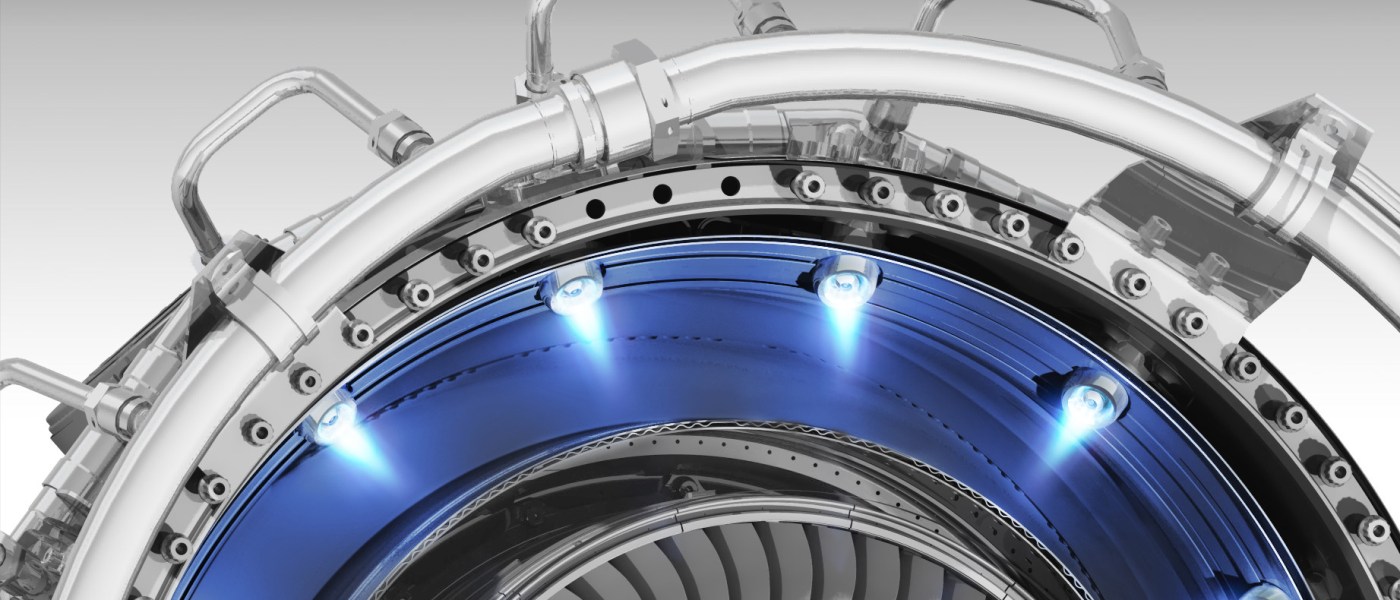

Funding for the first phase of the project will include fuel nozzle and combustor rig testing using hydrogen fuel, while future phases will target full engine ground testing. The PW127XT engine is the most advanced member of Pratt & Whitney Canada’s PW100 engine series, which has powered regional turboprop aircraft for forty years and accumulated more than 220 million flight hours. Launched in 2021, the PW127XT engine offers over 3% better fuel efficiency, 40% improved time on wing, and 20% reduced maintenance costs.

“We are thrilled to collaborate with INSAT and Pratt & Whitney Canada on this project,” said Raveel Afzaal, president and CEO of Next Hydrogen Solutions Inc. “The ability to produce green hydrogen at scale will be a critical enabler for reducing aviation CO2 emissions, whether using hydrogen as a direct fuel for combustion or as feedstock for SAF.”

As part of a second INSAT-supported project, Turbine Engine Advanced Materials for Efficiency (TEAME), Pratt & Whitney Canada will work with Derivation Research Laboratory (DRL) to explore advanced materials for hot section components of gas turbine engines, which will help to improve thermal efficiency and reduce fuel consumption and emissions. Pratt & Whitney Canada will lead the overall project providing both technical input and project management, while DRL will provide world-class materials testing capability for a wide variety of critical material properties.

About Next Hydrogen Solutions Inc

Founded in 2007, Next Hydrogen Solutions Inc. is a designer and manufacturer of water electrolyzers that use water and electricity as inputs to generate clean hydrogen for use as a green energy source or a green industrial feedstock. Next Hydrogen’s unique cell design architecture supported by 40 patents enables high current density operations and superior dynamic response to efficiently convert intermittent renewable electricity into green hydrogen on an infrastructure scale. Following successful pilots, Next Hydrogen is scaling up its technology to deliver commercial solutions to decarbonize transportation and industrial sectors. For further information: www.nexthydrogen.com

About Derivation Research Lab

Derivation Research Lab (DRL) was established in 2012 with an inherent focus on thermomechanical fatigue (TMF). Driven by passion, DRL offers expertise in modelling, research, and testing of high-temperature materials through a world-class facility located in Ottawa, Ontario. Visit www.DerivationResearchLab.com for more information.

About Pratt & Whitney

Pratt & Whitney is a world leader in the design, manufacture and service of aircraft engines and auxiliary power units. To learn more visit www.prattwhitney.com.

About RTX

With more than 185,000 global employees, RTX pushes the limits of technology and science to redefine how we connect and protect our world. Through industry-leading businesses – Collins Aerospace, Pratt & Whitney, and Raytheon – we are advancing aviation, engineering integrated defense systems, and developing next-generation technology solutions and manufacturing to help global customers address their most critical challenges. The company, with 2023 sales of $69 billion, is headquartered in Arlington, Virginia.

SOURCE RTX